KKK-T--683F

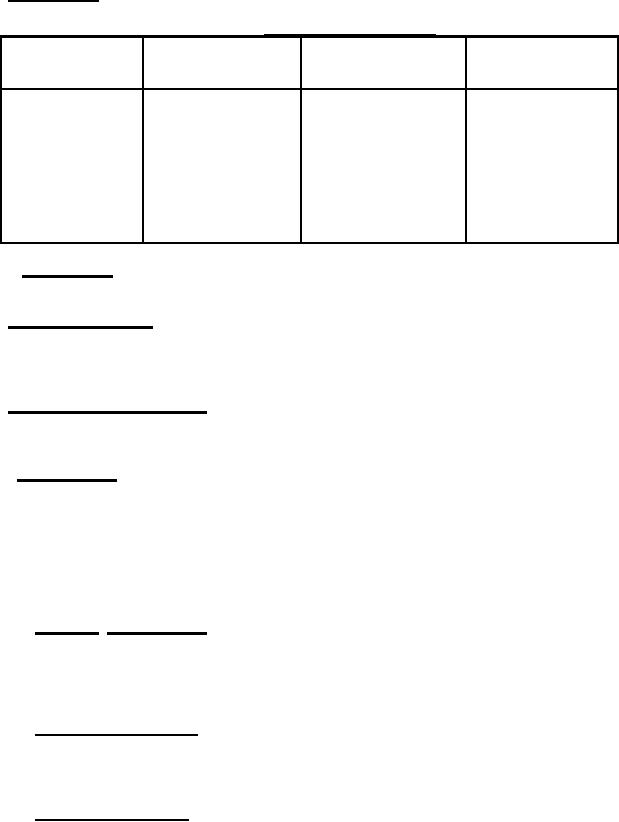

3.7 Dimensions. The dimensions of the trucks shall be as shown in table I.

TABLE I. Trucking dimensions.

Nose length

Overall

Truck

Overall

minimum

width

type

height

(inches)

(inches)

(inches)

6.313

61

Type I

24

6

45

17.5

Type II

6

52

18

Type III

13.5

50

33.75

Type V

6

60

24

Type VI

3.7.1 Tolerances. The dimensional tolerances for overall height and width

shall be +.50 inch, --O inch.

3.8 Color and finish. The portions of the truck normally painted shall be

cleaned, treated, and painted in accordance with MIL--T--704, type A. Unless

otherwise specified (see 6.2), finish coat shall conform to MPI #9, color gloss

yellow, No.13538 of FED--STD--595.

3.9 Identification marking. The truck shall be identified in accordance with

MIL--STD--130, and shall include the contractor's name or trademark, and part

number.

3.10 Workmanship. All parts, components, and assemblies of the truck,

including castings, forgings, molded parts, stampings, seals, and machined

surfaces shall be clean and free from sand, dirt, fins, pits, sprues, and other

harmful extraneous material. The truck shall withstand any operation specified

herein without deformation, breakage of connections or malfunction caused by

incorrect workmanship. Edges and surfaces exposed to operating and maintenance

personnel shall be smooth and rounded to the extent that a hazardous surface

does not exist.

3.10.1 Riveted connections. Riveted connections shall be in accordance with

SAE J492. Rivet holes shall be accurately punched or drilled and shall have

burrs removed. Rivets shall completely fill the holes. Rivet heads shall be

full, neatly made, concentric with the rivet holes, and in full contact with the

surface of the member, and shall not be cracked, fractured or broken.

3.10.2 Bolted connections. Bolt holes shall be accurately punched or drilled

and shall have burrs removed. Washers or lockwashers shall be provided. Self--

locking nuts are acceptable in lieu of standard nuts and lockwashers. All cap--

screws, bolts, and nuts shall be tight and correctly torqued.

3.10.3 Steel fabrication. Steel used in the fabrication of the truck shall

provide original quality surface finish and shall be free from kinks and sharp

bends. Steel having a corroded surface is not acceptable. The forming of

material shall be done by methods that will not cause damage to the metal.

Shearing and chipping shall be done neatly and accurately. Corners shall be

square and true. Burned surfaces of flame--cut material shall be free of slag.

Precautions shall be taken to avoid overheating, and heated metals should be

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business